The company’s management decided to develop and maintain an effective quality management System (QMS) that meets the requirements of international standards ISO 9001:2015 and API Spec Q1 in 2006, with the aim of continuous improvement of the company’s activities as one of the areas of strategic development. To implement the function of managing the corporate quality management system in the Neeco Group, a Quality Management System Service was created in the management Company structure.

Certification of Neeco’s two main manufacturing locations is evidence by our commitment to the development and implementation of a QMS system, as well as continuous improvement of its performance. The QMS that operates at the Company’s manufacturing locations meets the requirements of international standards ISO 9001:2015 and API Spec Q1 and is based on seven principles of quality management:

Besides the QMS, Neeco’s management have implemented and continue to maintain in good working standard a Health, Safety and Environmental Management system.

Using a Quality Management System ensures the management of the organizational, commercial and technical work of Neeco in the field of quality and guarantees complete fulfillment of consumers’ demands. As confirmation of this, efforts are underway to have the products and production processes of Neeco’s mills qualified by major international purchasers of pressure control products.

Neeco requires all its employees at its divisions to work in conformity with the requirements of facility quality manuals, the divisions’ current standards and other QMS documents, which is a guarantee that Neeco’s Policy and Goals in the field of quality are being implemented.

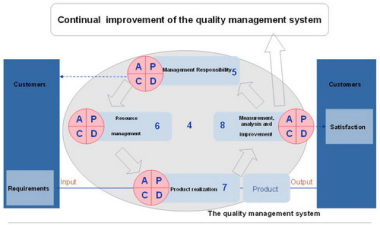

The Quality Manual is the main QMS document currently in use at each location. The Quality Manual describes the QMS concept developed in conformity with the requirements of the international standards ISO 9001:2015 and API Spec Q1. The QMS processes are described in the manual with a minimum of detail, and links are provided to the divisions’ standards or other QMS documents (SOPs), where the management of the respective processes are described in more detail.

As a means of carrying out and demonstrating the established processes, the Company has implemented and continues to support and improve the QMS in accordance with ISO 9001 and API Spec Q1.

The consistency and interconnection of the QMS processes in general form:

Check of functioning. Constant improvement.

The practical application of Neeco’s quality management system is closely monitored by the Quality Manager and Neeco’s management during the analysis of the management systems at all levels. An effective system of correcting and preventive actions, internal audits, monitoring of processes and products, targeted planning, and independent confirmation of conformity (of the certification and qualification of the management and product systems) makes it possible to assure our customers will receive products that meet the declared requirements just-in-time, as well as support the process of uninterrupted improvement of Neeco’s QMS.

Aviation, space and defense industries, are among the highest risk and most regulated business sectors in the world. Supplier qualification for these sectors, mandates suppliers meet the compliance requirements of a quality management systems, such as AS9100, AS9110 and or AS9120. The standard specifically addresses aerospace regulatory, safety and reliability requirements for any aerospace organization; from design and manufacturing to maintenance and distributors.

Credentials required to pursue domestic and international business opportunities, as a qualified supplier, are satisfied with certification. Every AS9100 certified company is included on the Online Aerospace Supplier Information System (OASIS) maintained by the IAQG. This searchable database is available to companies in the aerospace industry and includes information about each supplier with purchasing contacts. Consider OASIS as a free, aerospace marketing tool.

As an ongoing effort to maintain our leadership as a pressure control and flow control products manufacturer, we our in the process of attaining certification in AS9100D Aerospace Management Systems. This certification takes ISO9001:2015 to the next level – requiring an even greater degree of quality and rigor to receive.

For a supplier to receive the AS9100D certification, they must consistently deliver high quality materials on time. A staple in the aerospace/defense industry, most non-complex, complex and critical product users require their suppliers to receive this certification before agreeing to any contracts.

Pursuing the AS9100D certification gave us the opportunity to demonstrate our knowledge and expertise in quality management. This certification will reveal that we understand the best practices across the aerospace/defense industry – one of the most rigorous and quality-driven industries in manufacturing. By integrating these practices throughout our own organization, we will be able to further improve our current products and services.

Achieving AS9100D certification is a challenging task. So why did Neeco invest the time and resources necessary to prove ourselves in this area? For two reasons:

1. Neeco prides itself in being a leader in excellence. By becoming experts in the aerospace management system we gained tools and knowledge that will allow us to provide a higher level of quality and professionalism for all of our partners.

2. As the aerospace/defense industry continues to grow through innovation and new manufacturing techniques, Neeco has recognized a phenomenal opening.

We are proud of our team for pursuing this certification, and we are excited about the enhanced quality and support this will allow us to provide to our customers. Feel free to reach out to us if you have further questions about what this certification means and how it can assist us in better serving you.

© 2024 Neeco Industries, Inc. All Rights Reserved.